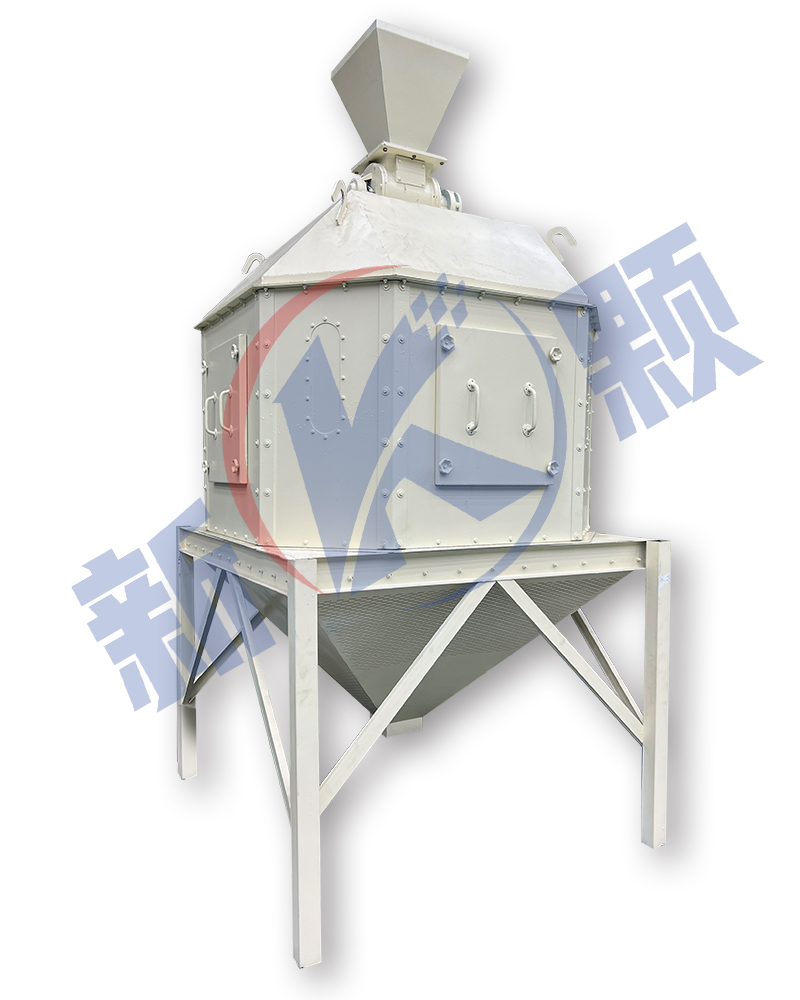

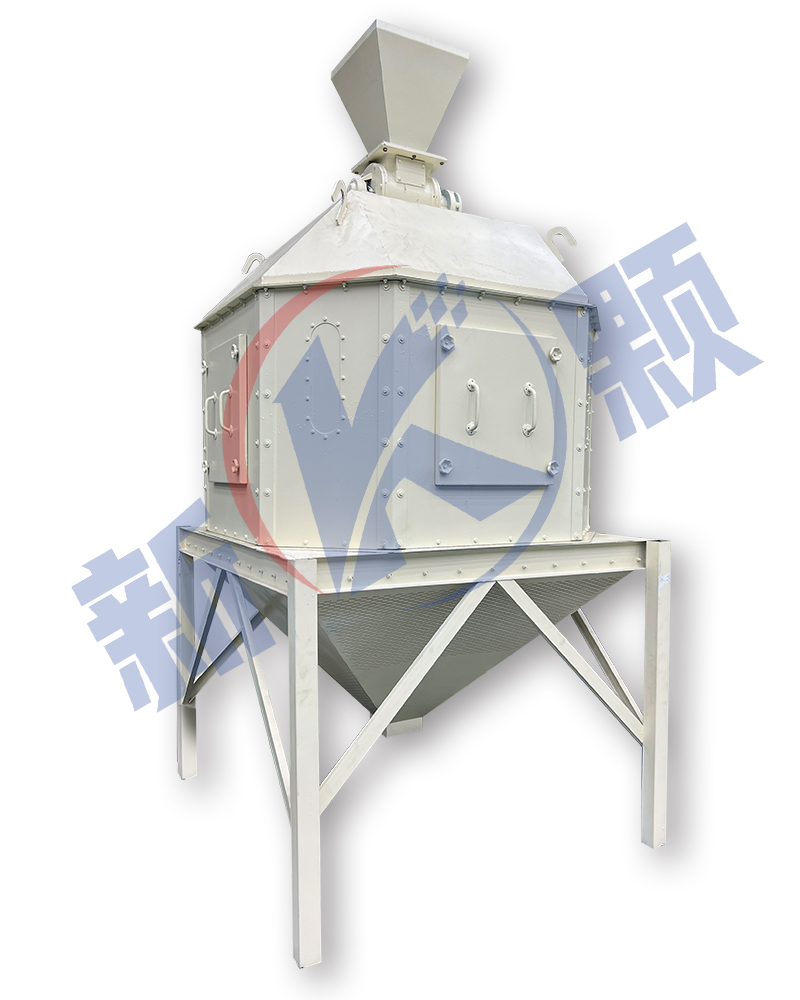

Medium sized cooling tower is a widely used heat exchange equipment in industries, air conditioning refrigeration, power and other fields. The following is a detailed introduction about it:

Structural composition:

Tower body: It is the outer shell of the cooling tower, which plays a role in supporting and protecting the internal components. Usually made of materials such as fiberglass and stainless steel, it has good corrosion resistance and strength, and can withstand various environmental conditions and workloads. The tower body of a medium-sized cooling tower is generally of moderate height to meet specific cooling needs and installation site requirements.

Packing: Located inside the tower, it is a key component for heat exchange. Its function is to increase the contact area between water and air, and improve the heat exchange efficiency. Common fillers include plastic fillers, metal fillers, etc., which are often in the shape of ripples or honeycombs. The packing of medium-sized cooling towers needs to have good heat dissipation performance, water resistance, and corrosion resistance to ensure long-term stable operation.

Fan: used to drive air flow and accelerate the heat exchange process between water and air. The types of fans include axial flow fans and centrifugal fans. Axial flow fans are commonly used in medium-sized cooling towers, which have the advantages of large air volume, low energy consumption, and smooth operation. The blade material of a fan is generally aluminum alloy or fiberglass, which has good strength and corrosion resistance.

Water distribution system: responsible for evenly distributing water on the packing material, ensuring that water and air can come into full contact. The water distribution system usually consists of water distribution pipes, nozzles, and other components, and its design and performance directly affect the cooling effect of the cooling tower. The water distribution system of medium-sized cooling towers needs to have good water distribution uniformity and stability to ensure the full utilization of water and efficient cooling.

Water collector: installed at the top of the cooling tower, used to collect water droplets carried in the air and reduce water loss. There are various forms of water collectors, such as corrugated, grille, etc., and their materials are generally plastic or fiberglass. The water collector of a medium-sized cooling tower needs to have good water collection effect and low air resistance to improve the operating efficiency of the cooling tower.

Water tank: used to store cooling water, serving as a buffer and regulating water volume. The material of the water tank is generally the same as that of the tower body, with good sealing and corrosion resistance. The water tank of a medium-sized cooling tower needs to have sufficient capacity to meet the cooling requirements and operational stability of the equipment.

Working principle: The working principle of a cooling tower is to use the direct or indirect contact between water and air to transfer heat from hot water to the air through evaporation and convection, thereby reducing the water temperature. The specific process is that hot water enters from the upper part of the cooling tower and is evenly distributed on the packing material through the water distribution system, forming a water film. Air is driven by a fan to enter from the lower part of the cooling tower, flows upward through the packing, and exchanges heat with the water film. During the heat exchange process, a portion of water evaporates into steam, taking away heat, while the remaining water falls into the water tank and is recycled.

characteristic:

Moderate cooling capacity: The cooling capacity of medium-sized cooling towers is generally between tens to hundreds of tons of water per hour, which can meet the cooling needs of medium-sized industrial production, air conditioning and refrigeration systems. Compared with small cooling towers, it has stronger cooling capacity and can handle larger heat loads; Compared with large cooling towers, it has a smaller footprint and relatively lower investment and operating costs.

High operating efficiency: Through optimized structural design and advanced components such as packing and fans, medium-sized cooling towers have high heat exchange efficiency and can lower the water temperature to the desired level in a short period of time. At the same time, its energy consumption during operation is relatively low, which can save users a lot of energy costs.

Strong adaptability: Medium sized cooling towers can be customized according to different working environments and cooling needs, such as adapting to different water quality, water temperature, climate conditions, etc. In addition, it can also be used in conjunction with various types of equipment and systems, such as central air conditioning systems, industrial production equipment, power equipment, etc.

Easy maintenance: The structure of a medium-sized cooling tower is relatively simple, and its components are easy to disassemble and install, making it convenient for daily maintenance and upkeep. At the same time, its reliability during operation is high, the failure rate is low, and it reduces the maintenance workload and cost for users.

Application areas: Medium sized cooling towers are widely used in industrial production, air conditioning refrigeration, power, chemical, metallurgical and other fields. For example, in industrial production, it is used to cool various mechanical equipment and hot water in the process; In central air conditioning systems, it is used to cool the cooling water in the condenser; In the power industry, coolants are used to cool equipment such as generators and transformers.

Scan to consult WhatsApp customer service

Scan to consult WhatsApp customer service  WhatsApp scan code

WhatsApp scan code

Customer Service Hotline+(86)186-3714-5777

7X24H Service Hotline+(86)186-3714-5777

Copyright © 2025 XinKe All Rights Reserved. Add:China Henan Zhengzhou Xingyang, Feilong Road and Xingyun Road,30 meters east and south of the road XML Technical Support