Airflow dryer is an efficient drying equipment. The following is a detailed introduction about it:

working principle:

The air flow dryer uses the principle of instantaneous air flow drying. Wet materials are sent into the hot air flow, and the materials flow together with the hot air flow. During the process of being carried by the air flow, the moisture on the surface of the materials quickly vaporizes, thereby achieving drying. The hot air flow provides heat to the material, causing water to evaporate, while the flow of air carries the material forward, accelerating the drying process. For example, by sending damp sawdust into a hot air flow, the sawdust will quickly dry under the action of the hot air flow.

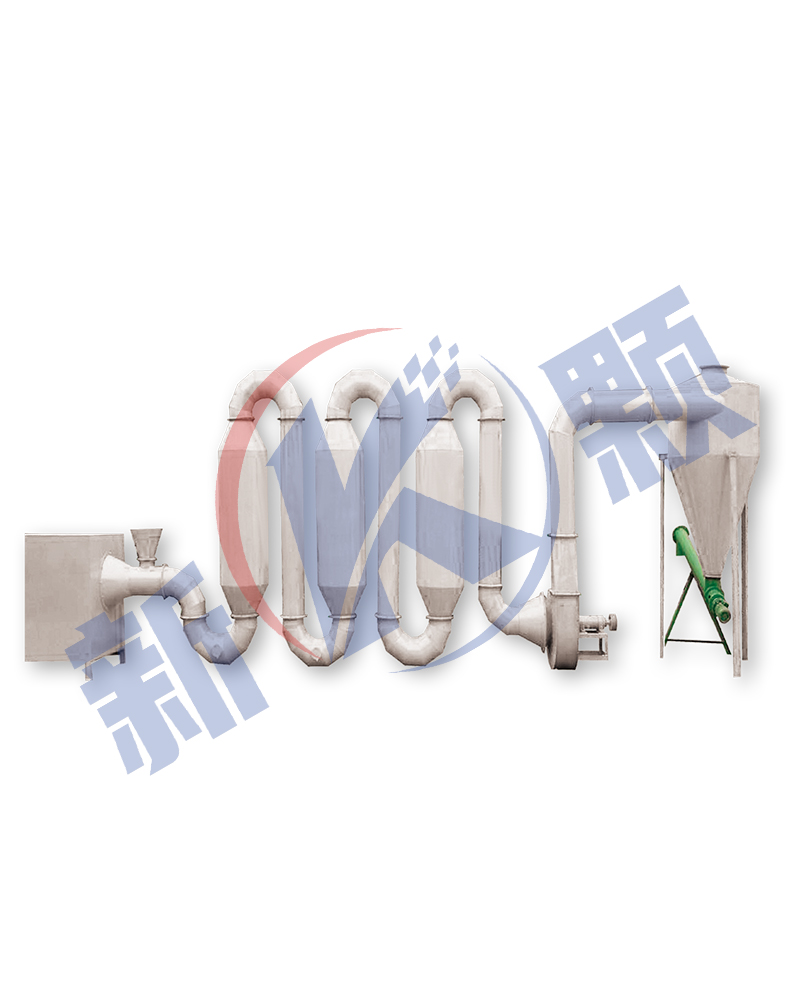

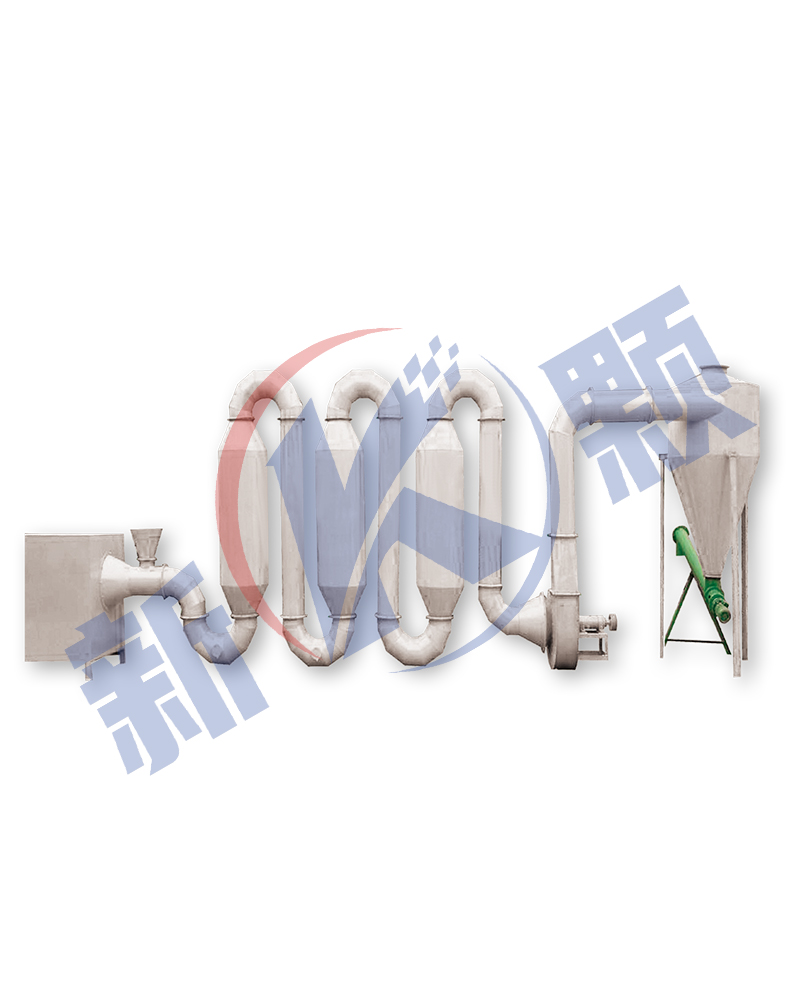

Structural composition:

Feeding device: used to transport the material to be dried to the inside of the dryer. For materials with high moisture content and prone to clumping during feeding, some equipment may also be equipped with a return device, which mixes a portion of the dried finished product with the wet material as a return to facilitate the drying operation.

Drying pipeline: This is the main place where materials exchange heat with hot air flow. Drying pipelines are usually upright pipes or pipes with a certain inclination angle, so that materials can move smoothly under the influence of airflow. Devices such as copying plates may be installed inside the pipeline to help disperse materials and increase the contact area with the hot air flow.

Heating device: responsible for heating the air and providing a heat source for the drying process. Common heating methods include fuel, gas, coal-fired hot air stoves, steam heat exchangers, or electric heating.

Fan: used to generate airflow, drive hot air to flow in the drying pipeline, so that materials can be suspended in the airflow and transported forward. The performance of the fan directly affects the speed and flow rate of the airflow, thereby affecting the drying effect.

Separators: Separate the dried material from the hot air flow. Common separators include cyclone separators, bag filters, etc. The cyclone separator uses centrifugal force to separate materials from the airflow, while the bag filter collects materials through filtration.

characteristic:

High drying intensity: Due to the high airflow velocity, the material is well dispersed in the gas phase, greatly increasing the drying area. At the same time, the dispersion and agitation during drying continuously renew the gasification surface, resulting in a strong heat transfer process that can quickly and effectively remove moisture from the material.

Short drying time: The contact time between the material and air is extremely short, usually around 0.5-5 seconds. It will not cause overheating or decomposition of heat sensitive or low melting point materials, and can maintain the quality of the material well.

High thermal efficiency: The material and gas are operated in parallel, and the material temperature and air temperature can reach a reasonable state. The drying time is short, so a higher drying temperature can be used, and the energy utilization rate is high.

Wide scope of application: It is suitable for drying all kinds of granular, flake and heat sensitive materials, such as starch, Rice noodles, food, medicine, chemical industry and other materials.

Simple structure: The equipment structure is relatively simple, occupies a small area, and has low investment and maintenance costs.

Type:

Straight tube airflow dryer: Wet material is added to the upright tube by a feeder, and the air is heated and blown into the upright tube. This type of structure is simple, easy to clean, and suitable for drying pharmaceutical products with high cleaning requirements. However, for some materials that require a longer drying time, a multi-stage series connection may be necessary.

Cyclone airflow dryer: The hot air carries the material into the cyclone dryer in a tangential direction, and the material rotates along the hot wall, in a suspended and rotating state for drying. The vessel wall can be equipped with a steam jacket to enhance the drying process, which is suitable for heat sensitive granular materials with strong hydrophobicity and no fear of crushing.

Pulse airflow dryer: It uses a method of alternating reduction or expansion of pipe diameter to make the airflow and particles flow at different speeds, increasing the relative velocity and heat transfer area between the airflow and particles, thereby enhancing heat and mass transfer rates, and increasing the drying time of materials in the expanded pipe.

Scan to consult WhatsApp customer service

Scan to consult WhatsApp customer service  WhatsApp scan code

WhatsApp scan code

Customer Service Hotline+(86)186-3714-5777

7X24H Service Hotline+(86)186-3714-5777

Copyright © 2025 XinKe All Rights Reserved. Add:China Henan Zhengzhou Xingyang, Feilong Road and Xingyun Road,30 meters east and south of the road XML Technical Support